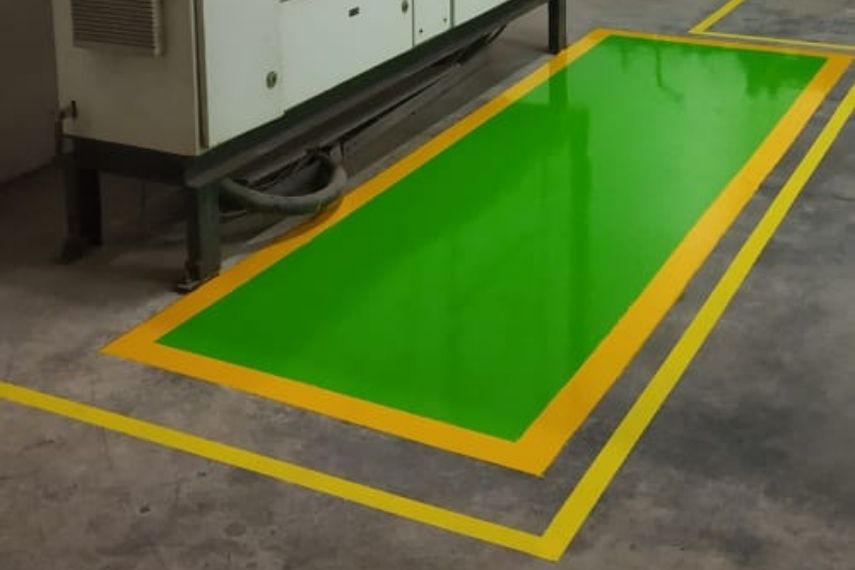

In order to guarantee a secure and effective working environment, choosing the appropriate electrical insulation floor coating is essential. In locations with electrical machinery and conductive materials, electrical insulation coatings offer a shield that guards against electrical risks, including electric shock and short circuits. Let’s review the essential factors to consider when selecting an electrical insulation floor coating, highlighting the significance of security, toughness, and suitability for the particular use.

Electrical Insulation characteristics:

The electrical insulation characteristics of the coating are of the utmost significance when choosing an electrical insulation coating. These characteristics define the coating’s capacity to properly insulate conductive materials and stop the passage of electrical current, reducing the risk of electrical hazards, including electric shock and short circuits.

Rating of voltage and dielectric strength:

The highest voltage an electrical insulation coating can tolerate without breaking down or leaking is indicated by its voltage rating. It is crucial to pick a coating whose voltage rating corresponds to the specifications of the electrical system in the particular setting. Its dielectric strength is the coating’s capacity to sustain electrical strain without experiencing an electrical breakdown. Reliable insulation is achieved by selecting a coating with a high enough dielectric strength, which stops electrical current from passing through and lowers the possibility of electrical accidents.

Poor conductivity

Low conductivity, or strong resistance to the flow of electric current, is a need for an efficient electrical insulation coating. Low conductivity reduces the risk of electrical shocks or short circuits by preventing the flow of electrical energy through the coating. By isolating conductive materials and limiting unintentional contact with live electrical components, ensuring that the coating has low conductivity contributes to creating a safe environment.

Insulation Resistance:

Insulation resistance refers to the coating’s ability to resist the flow of electric current across its surface. A higher insulation resistance indicates better insulation performance. Choosing a coating with a high insulation resistance is important, as this means a more substantial barrier against electrical currents. A coating with adequate insulation resistance reduces the chance of current leakage, ensuring electrical safety and minimizing the risk of electrical faults.

Temperature Resistance:

Another essential feature of electrical insulating qualities is temperature resistance. The coating should tolerate the higher temperatures in electrical systems due to regular operation or environmental causes. When exposed to heat, a coating with high-temperature resistance keeps its insulating qualities intact, preventing breakdown or deterioration that reduces efficiency.

Compliance with Safety Standards:

When selecting an electrical insulation coating, it is crucial to consider its compliance with relevant safety standards and regulations. Various industry-specific standards set guidelines for electrical insulation properties, ensuring the coatings meet minimum requirements for safety and performance. Selecting a coating that complies with these criteria guarantees that the insulating qualities have been examined and approved by reputable organizations.

Suitable Materials:

Specific flooring materials and coatings are needed for various uses and situations. The compatibility of the coating and the underlying flooring material must be taken into account when choosing an electrical insulation floor coating. The coating should adhere to the surface and form a strong bond to provide long-lasting protection. Factors such as the composition of the flooring material, its porosity, and the presence of contaminants should be considered to ensure proper adhesion and compatibility.

Durability and mechanical strength:

To meet the demands of a given application, electrical insulation floor coverings should have exceptional mechanical endurance. The coating should withstand collisions, abrasion, and heavy loads. A long-lasting coating reduces the possibility of chips, cracks, or peeling, which might impair the insulation’s qualities, create safety risks, or necessitate repeated repairs.

Easily Maintained:

It is essential to consider maintenance requirements when choosing an electrical insulation coating. A coating that is simple to maintain provides effective maintenance, minimizes downtime, and increases the longevity of the flooring.

Easy cleaning techniques:

The amount of time and effort needed for maintenance is decreased by a coating that makes straightforward cleaning processes easier. The coating should work well with common cleaning chemicals and techniques so that regular cleaning can be done effectively. Without the need for specialized cleaning tools or methods, smooth and non-porous coatings make removing dirt, dust, and other debris simpler, guaranteeing a clean and hygienic atmosphere.

Resistance to Abrasion and Wear:

Durability plays a vital role in ease of maintenance. An electrical insulation floor coating that is resistant to abrasion and wear minimizes the need for frequent repairs or replacements. Such a coating withstands the demands of daily foot traffic, equipment movement, and other activities without deteriorating or losing its protective properties. With a resilient coating, facility managers can focus on regular maintenance rather than constant repairs.

Low-Frequency Recoating:

Selecting an electrical insulation floor coating that requires periodic recoating is advantageous in terms of maintenance. A long-lasting coating significantly reduces the need for frequent reapplication, saving time, labor, and material costs. By choosing a coating with excellent durability and resistance to degradation, facility managers can establish a maintenance schedule that prioritizes other aspects of facility upkeep.

Compatibility with Existing Maintenance Equipment:

An easily maintainable electrical insulation coating should be compatible with existing maintenance equipment and tools. Compatibility ensures that standard cleaning machinery, such as scrubbers or sweepers, can be used without causing damage to the coating. It eliminates the need for investing in specialized equipment and streamlines the maintenance process.

Clear Maintenance Guidelines:

The coating manufacturer’s detailed maintenance instructions make maintenance simple. Facility managers and maintenance workers can complete jobs more successfully when given clear instructions on suggested cleaning techniques, appropriate cleaning products, and frequency of maintenance. Manufacturers frequently offer instructions particular to their coatings, ensuring that the floor coating is kept in top condition for its useful life.

Conclusion:

Maintaining a secure and productive workplace requires choosing the appropriate electrical insulation floor covering. It is important to carefully evaluate factors including electrical insulating qualities, material compatibility, chemical resistance, durability, slip resistance, and ease of maintenance. Organizations can provide dependable electrical insulation and reduce the danger of electrical hazards in locations where electrical equipment and conductive materials are present by giving priority to safety, durability, and compatibility with the particular use. The facility will be safer, more durable, and more effective overall if the suitable electrical insulation floor coating is chosen and installed.