The design of VLSI chips is essential to the creation of cutting-edge electronics, including smartphones, computers, medical equipment, and smart homes. Maximizing performance while decreasing power consumption and error rates requires a VLSI chip design that is both efficient and dependable. Key elements of efficient and reliable VLSI chip design will be discussed in this article, such as VLSI layout design, testing, verification, optimization techniques, challenges, considerations, tools, technologies, quality assurance and control, collaboration, and communication.

Definition of Very Large Scale Integration Chip Design: Methodology and Goals

The goal of very-large-scale integration (VLSI) chip design is to develop integrated circuits that can carry out complicated tasks while consuming as few resources as possible. Minimizing production time and costs while maximizing performance, reliability, and efficiency is the holy grail of VLSI chip design. VLSI chip design is a multi-step process that begins with conceptualization and continues through architecture design, layout, and, finally, testing.

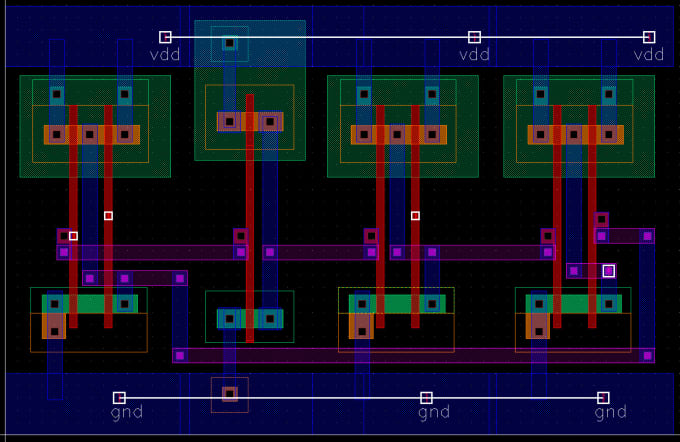

Components, Layout, and Wiring: Vital to Efficient and Reliable VLSI Chip Design

The success of a VLSI engineering in USA relies on a number of factors, including careful selection of components and materials, an efficient and effective layout, and wiring that is free of interference and noise. Choosing the right transistors and capacitors is essential for maximum efficiency and dependability. When properly laid out, the distance between components can be minimized, and improper wiring can be avoided.

Guidelines for Testing, Modeling, and Verifying Very Large Scale Integration (VLSI) Chips

Best practices for chip design companies include testing, simulation, and verification. By comparing the results of different scenarios and designs, testing ensures that the chip functions as intended. In order to verify a chip, its design must be checked to make sure it is error-free and will perform as expected. By catching mistakes and fixing them before they cost too much time or money to fix, these procedures help streamline the design process.

Maximizing Performance While Lowering Power Consumption and Noise in VLSI Chip Design

Minimizing power consumption, lessening noise and interference, and increasing performance are all methods that can be used to improve the design of VLSI chips. Power gating and voltage scaling are two methods for conserving energy, and grounding and shielding can cut down on unwanted noise and interference. Parallel processing and algorithm optimization are two ways to boost performance.

Size, Complexity, and Interconnectivity as Challenges and Considerations in Very Large Scale Integration Chip Design

Size, complexity, and interconnection are all factors to think about while designing a very large-scale integrated circuit (VLSI) device. Finding a happy medium between space requirements, intricacy, and speed is a difficult task. This necessitates giving serious thought to the manufacturing process and prices, in addition to the functional requirements of the chip.

VLSI chip design also takes interconnectivity into account. Keeping noise and interference to a minimum is essential for proper component communication.

Advances in VLSI Chip Design Tools and Technologies: Software, Hardware, and Manufacturing Methods

VLSI chip design has been made much easier by developments in software, hardware, and manufacturing techniques. Advances in manufacturing techniques allow for the development of increasingly sophisticated and efficient chips, and powerful design software and simulation tools enable designers to generate and test designs fast and efficiently. Before committing to fabrication, designs can be created and tested on hardware like field-programmable gate arrays (FPGAs).

Guaranteeing Reliability and Consistency in VLSI Chip Design with Quality Assurance and Control

In order to guarantee the dependability and uniformity of VLSI chip design, quality assurance and control are essential. This involves checking that the design is error-free and compliant with all criteria and standards before it is manufactured. As part of quality control, products are put through rigorous testing to guarantee they are reliable and up to par in terms of performance.

Cooperation and Conversation in Very Large Scale Integration Chip Development

Successful VLSI chip design relies heavily on teamwork and open lines of communication with clients, customers, and business partners. All stakeholders in the design process should be kept abreast of developments and revisions through clear and consistent communication. Everyone involved in a collaborative effort needs to have a voice and provide criticism, and there needs to be a firm understanding of who does what. To make sure everyone is on the same page and moving in the same direction, it’s important to have regular meetings and status reports.

To achieve maximum efficiency, low power consumption, and minimal noise and mistakes in today’s electronics, VLSI chip designs must be both efficient and dependable. Proper component selection, optimum layouts and wiring, testing and verification, and optimization methodologies are all essential for designing VLSI chips.

The design’s scale and complexity, as well as the need for effective interconnectivity and communication among components, present difficulties. VLSI chip design has been made much easier by developments in software, hardware, and manufacturing techniques, yet quality assurance and control remain essential for maintaining dependability and consistency.

Successful VLSI chip design relies heavily on teamwork and open lines of communication with clients, customers, and business partners. Designers may make VLSI chips that are efficient and dependable enough for today’s electronics by adhering to these best practices and methods.

Minimizing power consumption, lessening noise and interference, and increasing performance via parallel processing and efficient algorithms are all strategies for optimizing VLSI chip design. When designing a VLSI chip, it is important to strike a balance between the trade-offs of size, complexity, and performance and to make sure that components can effectively connect and communicate with one another.

VLSI chip design has been made much easier by developments in software, hardware, and manufacturing techniques, yet quality assurance and control remain essential for maintaining dependability and consistency. VLSI chip design success also relies heavily on teamwork and open lines of communication with clients and other business associates. Designers may make VLSI chips that are efficient and dependable enough for today’s electronics by adhering to these best practices and methods.

Conclusion

Finally, very large-scale integration of VLSI chips is an involved and difficult process that calls for meticulous preparation, close attention to detail, and communication between hardware design in USA, clients, and collaborators. Selecting appropriate components, developing an optimal layout, and designing efficient wiring that reduces noise and interference are all crucial parts of constructing a dependable and functional VLSI chip. Testing, simulation, and verification, along with modular design and Design for Testability (DFT) approaches, are all recommended best practices for designing VLSI chips.