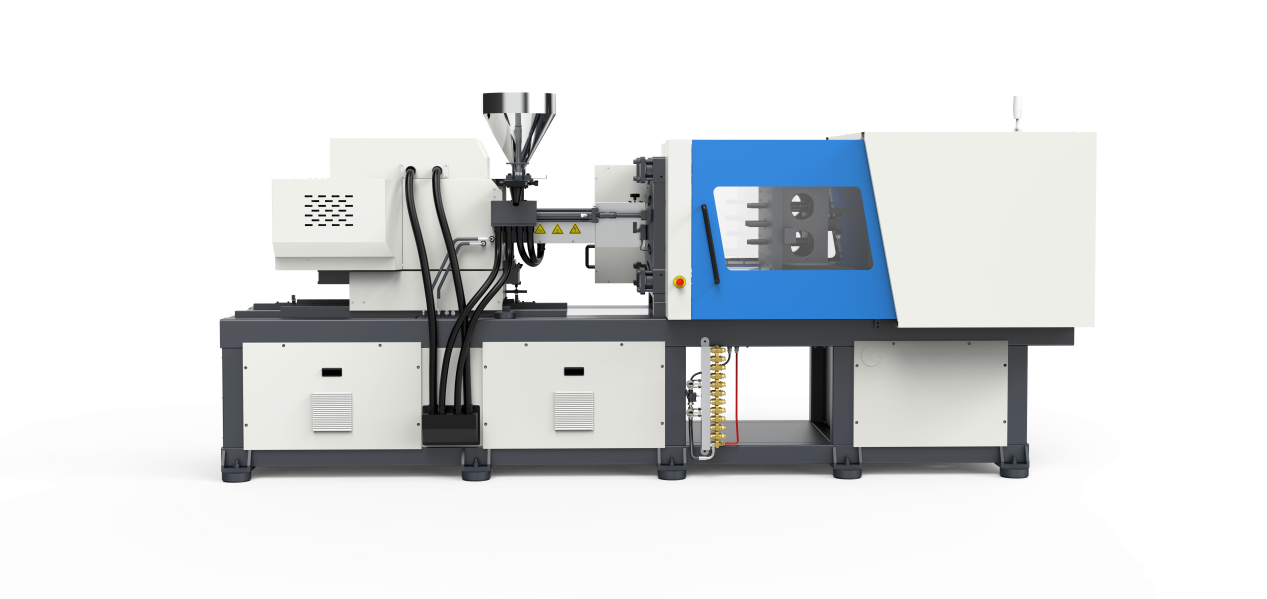

Injection molding is not a new technology. It’s been around for ages and is used for everything from making Lego bricks to plastic handles on kitchen utensils. The process is simple: the material you want to use is melted in a high-temperature injection molding machine. A plunger then injects the liquid plastic into a mold, where it remains until it cools down enough to be ready for use. In this article, we’ll give you an overview of what a large injection molding machine can do for your business!

A large injection molding machine is an excellent investment for any plastic parts business!

An injection molding machine is an excellent investment for any plastic parts business. If you’re looking to save money and time while increasing the efficiency of your company, a large injection molding machine can help. The benefits include:

Making more plastic parts at a faster rate. The ability to produce more products in less time means customers can get their orders faster. This makes them happy (and keeps them coming back) while saving you money on labor and transportation costs associated with shipping products from suppliers worldwide!

Produce a higher quality product from start to finish, using higher quality raw materials when making the molds. This results in a more robust finished product that will last longer without wear and tear from everyday use. Plus, since there are no longer any seams between parts during assembly, which could cause them to fall under pressure, there’s no need to worry about leaks down the line, either!

Large injection molding machines are suitable for all different types of plastic products!

It is suitable for the manufacture of various types of plastic products. Using the device to create parts, containers, furniture, and toys is possible. The choice of what you want your finished product to look like depends on how much money you are willing or able to spend on materials; and how much time is available for production.

The more expensive options will result in higher quality results because they use better materials that last longer than cheaper ones would; however, this comes at a price tag that may not be worth it depending on what kind of business you’re running or if it’s just something personal like making toys for family members as gifts (which we highly recommend doing!).

Large injection molding machines will help you save money and time and improve efficiency!

Large injection molding machines will help you save money and time while making your company more efficient. This is because the device has a higher productivity rate than smaller versions, which means it can produce more parts in a shorter time. This will reduce waste, increase quality, and reduce product lead time.

The cost savings come from producing more parts in less time at lower costs per unit (Cpk). The Cpk measures how well you are doing compared to what is possible given the same level of resources used by other companies producing similar products or services as yours in the same industry segment with similar requirements regarding quality standards.

An injection molding machine can help you turn your idea into a reality!

An injection molding machine can help you turn your vision into a reality. The first step in getting your product out there is to design it, and that’s where an injection molding machine comes in. It will help you design and produce your product so that when it’s finished, all that remains is testing and shipping the finished product!

Injection molding machines are also suitable for manufacturing; if there are any issues with how something is manufactured or produced, companies like ours can use these machines to fix those issues before shipping them to possibly from us. Customers who buy them!

Large injection molding machines are suitable for companies and factories!

Injection molding forces molten plastic into a mold that cools and hardens. The material is forced into the cavity of this piece, where it cools down and becomes solid.

They can make many different types of parts, mostly a matter of how much time you have and what you make. They can also use various materials such as metal, wood, or plastic (among others). These machines provide businesses with several advantages, including:

Increased productivity – since these machines work quickly and efficiently, there’s less time spent waiting around for things like glue guns or paint brushes to dry before moving forward with other tasks explicitly related to completing one objective within an overall goal involving multiple steps taken sequentially over time.

To sum up

The description of the above article can let you know what a large injection molding machine can do for you. It helps you produce more products simultaneously and saves time, among other things. If you have any questions about large injection molding machines, please contact us by email.